3DSI has been involved with 3D Printing and Urethane Casting for the last 20 years. We have watched 3D Printing evolve from the early SLA prototyping machines in the 1990's to the advanced digital manufacturing solutions available today. Our customer service and "no-hassle" guarantee are second to none in this industry. We are excited to provide our customers with the finest quality parts at the best possible value. Our team can provide design support as well as advice on how to best make your product with respect to the desired outcome.

At 3DSI we offer 3D Printing and Urethane Casting, but most importantly, we offer a complete turnkey solution that goes well beyond your print. We offer "Production-Level" 3D Printing & Design Services which opens the door to Mass Customization. There are many suppliers that make parts out of weaker materials without the ability to scale production. We offer engineered-grade materials that will stand the test of time right off of the 3D Printer. We are a true additive manufacturing company offering production parts with the ability to scale your project into different manufacturing mediums such as Urethane Casting & Injection Molding. We offer many different surface finish options as well as different durometers of material to choose from that closely simulate every plastic & rubber available.

We offer SLA & FDM for print technology. Many different levels of surface quality can be achieved directly off of the printer by adjusting layer height, or during the post-processing step after the part build. Alternatively, we can eliminate some or all of the stair steps with our casting process (depending on your specific needs) - see the bottom left corner and lettering on the business card below as an example of a typical request. Urethane cast parts can simulate virtually any plastic on the market, and in most cases, the performance will exceed that of its respective counterpart! Regardless of your goal being material performance or aesthetic surface finish, we have your covered at 3DSI!

Examples of A, B, and C level finish.

All 3D print service bureaus are NOT created equal. At 3DSI we build relationships with our customers. We know the key to a successful partnership is good bi-directional communication. This candid back and forth dialogue insures we will meet or exceed customer expectations on every single order. We look at the end goal of a given project and offer advice along the way to deliver exceptional results. Geometry conditions can create a number of challenging situations that translate to part defects if not properly addressed up front. How do we know? Because it happens to the best of us, and yes we have our own wall of shame (parts failures that we use as training opportunities for our staff). Our goal is always to create the best looking part with the least amount of support marks. With this goal comes a delicate balance between part perfection and part failure. At 3DSI we customize the support arrangement for every job to deliver the best possible outcome for our customers. The difference between 3DSI and other service providers is that we DO NOT ship the defects listed below. We also offer print correction when standard tolerances directly off of the printer are not good enough for your specific application. We go the extra mile to balance accuracy requirements, support arrangement, build orientation, proper part cleaning, and cure time to deliver an exceptional result every single time. This is in fact our promise and guarantee to our customers. See comments from our customers regarding our part quality here.

The image below represents the SLA resins that we stock (Non-stock materials are subject to the manufacturer lead-time).

SLA Resin Material Properties Data Sheet - This link will open a PDF file that contains the properties for the most of the above pictured materials. Specific material property data sheets can be sent upon request.

SLA Resin Mechanical Properties Explained - This link will further explain the performance characteristics found in the material properties data sheet above.

We also stock a variety of FDM thermoplastic materials in various colors - (Rigid PLA and Flexible TPU).

With over 20 years of experience in engineering design and 3D Printing, we can help you get your product to market faster than the competition. Our goal is to offer a pricing structure that individual inventors can afford versus the typical cost most encounter with the big 3D Printing/SLA contractors and design firms. We can also help with Patent & Trademark Law, Proof-of-Concept, and Short-Run Production. We have domestic and international partners that can step in and offer a wide range of manufacturing processes when it's time to scale. We look forward to working with you on your next big idea! Please feel free to give us a call or drop us an email to request samples or a quote - support@go3dsi.com

We can help you with:

Design & Proof-of-Concept

Retail Packaging

Brand Development

Patent & Trademark Law

Website Development & ECommerce

Short-run production for market testing

Manufacturing at any scale - Both Domestic & International

For corporations we also offer:

Prototyping workshops for your in-house design team - 3D Printing and Urethane Casting

Patent drafting services

Training on Parametric 3D Modeling & infrastructure setup

Business card that demonstrates our Urethane Casting and 3D Printing processes as well as standard surface finishing techniques.

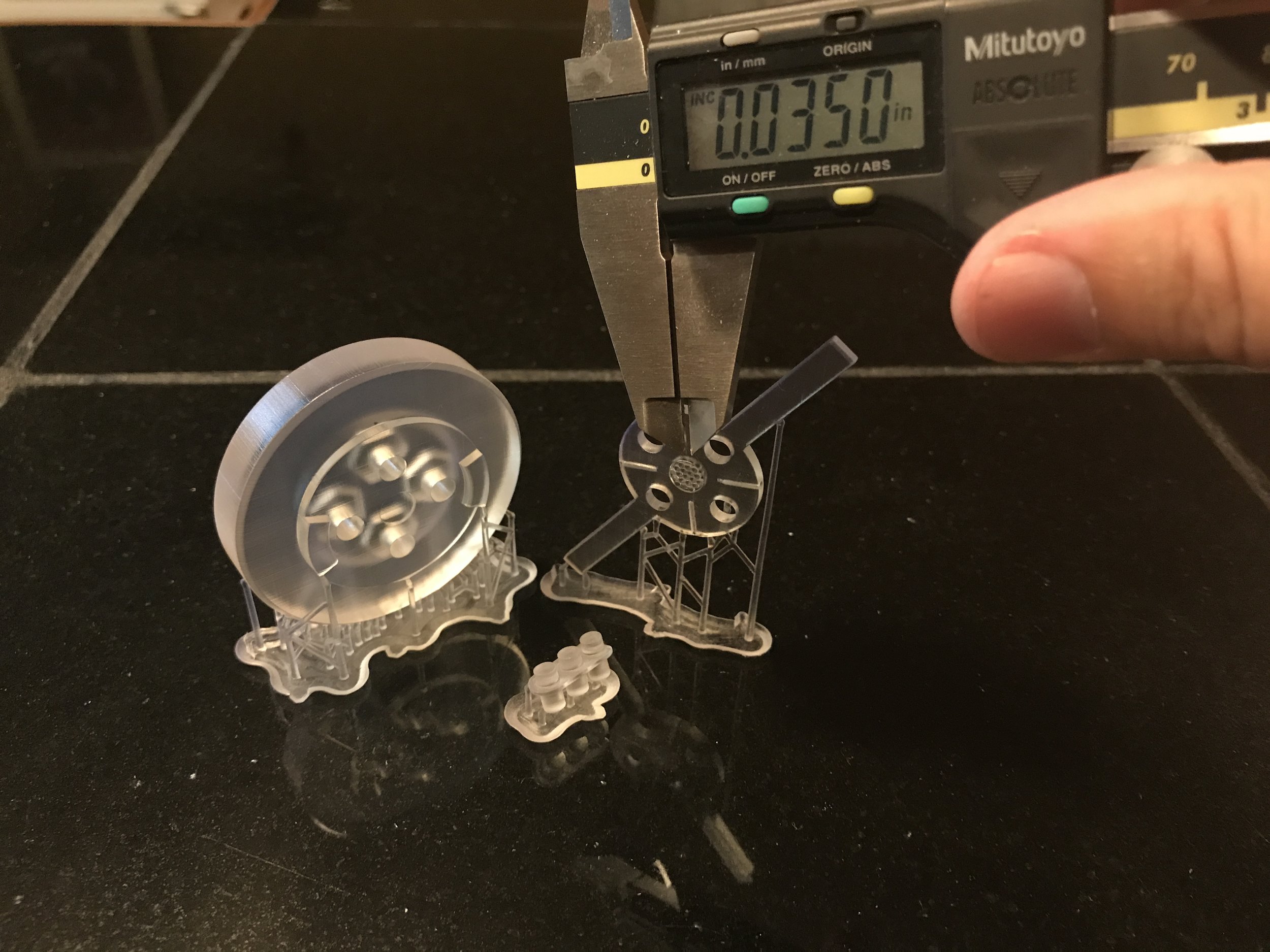

Example of the small but accurate details capable with SLA 3D Printing.

Example of Durable SLA Resin, which closely mimics Polypropylene.

From design to reality with the SLA 3D Printing process.

Example of the beautiful 25 micron layer finish on an SLA 3D Printed part.

Example of our ability to add inserts/screws during the Urethane Casting process.

Example of a typical Urethane Cast part and mold - UV stable crystal clear casting material.

Example of large-format prototyping off of our machines - Foredom Bench Lathe Finishing Station Design and Prototype.